SUS Pet Food 500kg / H Extruder Machine Automation

Introduction

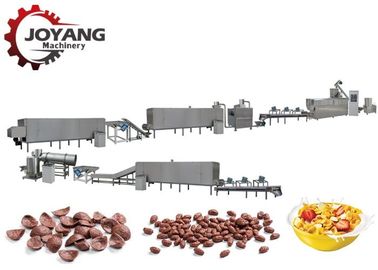

Pet food production line endows pet food with novel shape, taste and color, and adapts to the developing pet food market with scientific nutrition ratio and easy digestion. Over the years, the company's efforts in extruder technology advantages are fully reflected in the pet food production line. Simple operation, easy to learn, parameter control, to ensure that the product in a specific temperature, pressure, humidity and time to complete. Reasonable structure design, special materials, fast self-cleaning performance to ensure the stability of the machine and easy maintenance. Rich and colorful shape and taste to meet the requirements of a variety of pet food. Pet food production line consists of powder mixer, twin-screw extruder, air blower, dryer and seasoning machine.

Paramenters

| Model |

JY-65 |

JY-70 |

JY-85 |

| Installed Power |

76kw |

95kw |

178kw |

| Power Consumption |

54kw |

66kw |

125kw |

| Output |

140-160kg/h |

240-260kg/h |

500 kg/h |

| Dimension |

17x2x2.5m |

22x2x2.5m |

26x2x3.5 m |

Final product

Pet food, diameter from 1mm to 14mm, length customized, color customized.

Flow chat

Mixer → Screw conveyor → Twin-screw extruder → Hoister → Dryer → Hoister → Roller and flavor feeder → Oil sprayer

Details

Mixing machine: Add a certain percentage of water to the raw material corn flour, rice flour, soybean flour, meat flour, cereal flour, additives, etc. and mix well.

Screw conveyor: Use the motor to drive the spiral conveying to transfer the mixed raw materials to the feeding hopper of the extruder to ensure convenient and fast feeding.

Twin-screw extruder: In the case of high temperature and high pressure environment and screw extrusion, different feeds can be produced by adjusting the process. The specific particle size and shape can be changed.

Sifter: sieve away excess material and particles at the end of the year to ensure quality while ensuring the reuse of raw materials.

Air conveyor: Convey feed to the oven.

Multi-layer oven: The oven is mostly an electric oven. The temperature is adjusted by the control cabinet between 0-200 degrees. The interior is a stainless steel double-layer mesh bag to reduce the moisture of feed particles, promote the maturation rate and increase the shelf life.

Flavoring line: According to the output and product properties, the oil is sprayed on the surface of the feed dust and spices, sprinkle evenly.

Cooling conveyor: reduce the temperature of frying and feed, promote the solidification of fat, reduce the temperature of particles, and facilitate packaging.

Packaging machine: manual sealing machine and automatic packaging machine can be used.

Features

1. The operation is simple, greatly reducing the difficulty of operation, and the equipment is fast to use. The unqualified rate of products is greatly reduced and the production efficiency is improved. The whole production line includes: raw material receiving system, crushing system, mixing system, extrusion system, drying system, spraying system, cooling system and packaging system.

2. The whole production line needs very little labor, which greatly reduces the labor cost and ensures the product output.

Packing and shipping

Packing:

Inside: plastic bag for fish feed making machine.

Outside: wooden case (adopt the wooden case or wooden pellets depended on clients' requirement).

Transportation:

Shipping, train, express, or upon clients’ demands.

Our Services

1, Free consultation service before, during, and after sales.

2, Free project planning and design services upon clients' special demands.

3, According to customer’s factory size, factory layout can be provided in advance.

4, Debugging and inspecting of equipment until everything is functional before leaving the factory.

5, Overseas installation and training of equipment maintenance and operating personally.

6, Provide basic production techniques and formulas.

7, 1 year complete warranty for our machine.

FAQ

Q: Could you supply all the parameters about the machines?

A: Of couse. We are delighted to supply all the informtion that you want to know.

Q: How long is your delivery timre?

A: Generally speaking, it is 7 days if the machines are in stock. Or it is 25 days if the goods are out of

stock.

Q: How about the after sale service?

A: We will send our engineers to your factory for installation and training.

Contact with us

If you have any questions and you are interested in our fish feed production line, don't hesitate to contact with us. Your inquiry will be highly appreciated and we will give you the best price and service in order to make a long business relationship with you in the future!

Mr. Jack Bing

Cell phone: +8613589061075 (Whatspp and Wechat ID)

Email: sales03@joyangmachine.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!